Share

Activated Carbon Filter

Still thinking about it? If you want to get a sample first,Please contact us!

Product Categories:

HEPA Filter

Keywords:Yanning

Here is the placeholder text

- Product Description

- 认证

-

Product Description:

The activated carbon panel filter can be made of aluminum frame, galvanized frame, stainless steel frame, etc. The thickness can be made according to customer requirements. The filter material is made of high-quality activated felt or activated carbon fiber, which can be produced by expanding area pleating process or flat-plate processing. After the activated carbon plate filter is installed, due to its own structure, it also has a large dust holding capacity and a low initial resistance.

Application:

Airport, subway, automobile, electronic factory, nuclear power plant, home use, hospital and waste water treatment etc.

Product Feature:

◆ Strong suction rate

◆ Excellent deodorizing effect

◆ Easy to use, low operating cost

◆ Long filter life

Product Parameter:Dimension(WxDxH)nches Dimension(WxDxH)mm Air Volumem³/h Initial

PressureMaterial Adsorption Performance

Deodorizing Performance

Frame Filter Medium 12x12x1 95x295x21 800

55(pa)Aluminum Alloy

Galvanized PlateActive felt

Active carbon fiberBenzene>30%

lodine >80mg

30 Type

Ethanethiol>80%

30 Type

Trimety este >80%12x20x1 295x495x21 1300 16x20x1 395x495x21 1750 12x24x1 295x595x21 2200 24x24x1 595x595x21 3200

Prepare for shipment

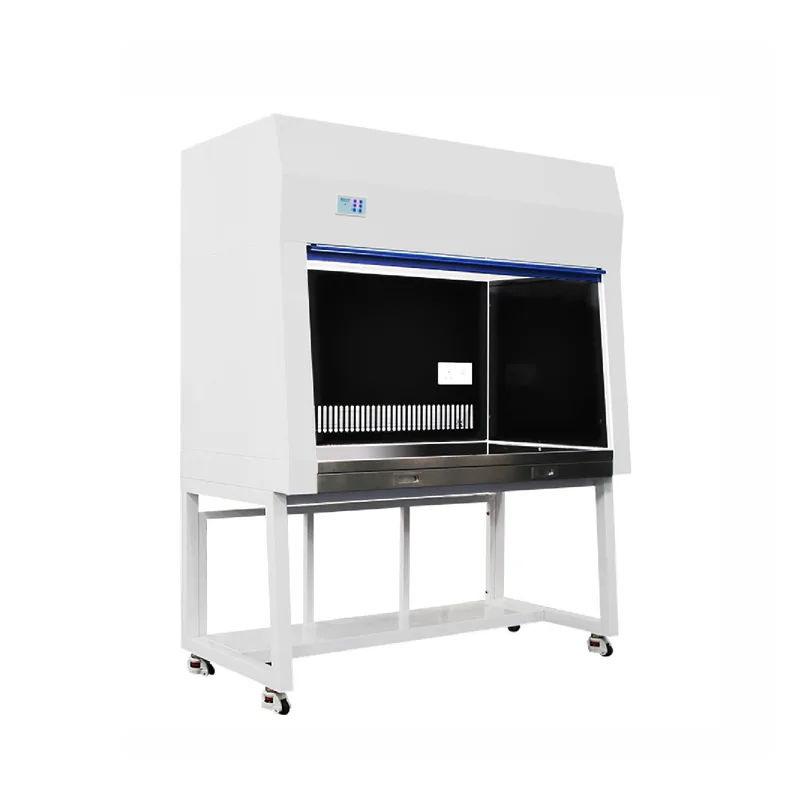

Air Filter Workshop

FFU Workshop

Medical Equipment Workshop

Sheet Metal Workshop

Welding Group

Laser Engraving Machine

Assembly Workshop

Sheet Metal Group

Appearance scene

Applications

Case studies are essential for advancing knowledge, improving skills, and driving innovation in the field of air purification solutions. It enables professionals to learn from both successes and failures, ultimately leading to more effective and sustainable air quality management practices.

Semiconductor

Vehicle Making

Education and Training

Electrical and Electronics

Healthcare and Hospital

Advantage-Why Choose Us?

In-House/ Manufacturing & Quality Control

Our in-house manufacturing capabilities empower us to maintain strict control over the quality of every component and leverage cutting-edge technologies that adapt to the evolving needs of your industry and benefit from the latest advancements in air purification, cleanroom design, and modular operating room technology.

Experienced Engineering Team

Our in-house manufacturing capabilities empower us to maintain strict control over the quality of every component and leverage cutting-edge technologies that adapt to the evolving needs of your industry and benefit from the latest advancements in air purification, cleanroom design, and modular operating room technology.

In-House/ Manufacturing & Quality Control

Our in-house manufacturing capabilities empower us to maintain strict control over the quality of every component and leverage cutting-edge technologies that adapt to the evolving needs of your industry and benefit from the latest advancements in air purification, cleanroom design, and modular operating room technology.

HONOR CERTIFICATE

FAQS

Q

What type of company are you? Where are you located?

A

We are a company integrating industry and trade, located in Dongguan City, Guangdong Province, China. You are welcome to visit us anytime to see our factory and products.

Q

Do you provide samples?

A

Yes, we can provide samples, but a sample fee and shipping cost are required. The sample fee can be refunded after confirming the order for the same model product.

Q

How long is your lead time?

A

For small batch production, the delivery time is 10-15 days after receipt of payment and specification confirmation. For large batch production, the delivery time varies depending on the type of equipment and order quantity.

Q

Do you conduct leakage tests on filters?

A

Yes. We possess specialized apparatuses for testing the airtightness of filters.

Q

What certifications do you have?

A

We have ISO, CE, and TUV certifications. If you require other certifications, we can apply for them.

Q

What is the warranty period? Can it be extended?

A

The warranty period is 12 months from the installation and commissioning date. Extended warranty is available for an additional fee.

Field Case

Case studies are essential for advancing knowledge, improving skills, and driving innovation in the field of air purification solutions. It enables professionals to learn from both successes and failures, ultimately leading to more effective and sustainable air quality management practices.

FFU

FFU

FFU

FFU

FFU

FFU

Consultation

We will contact you within one working day. Please pay attention to your email.